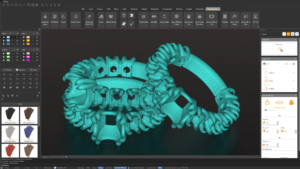

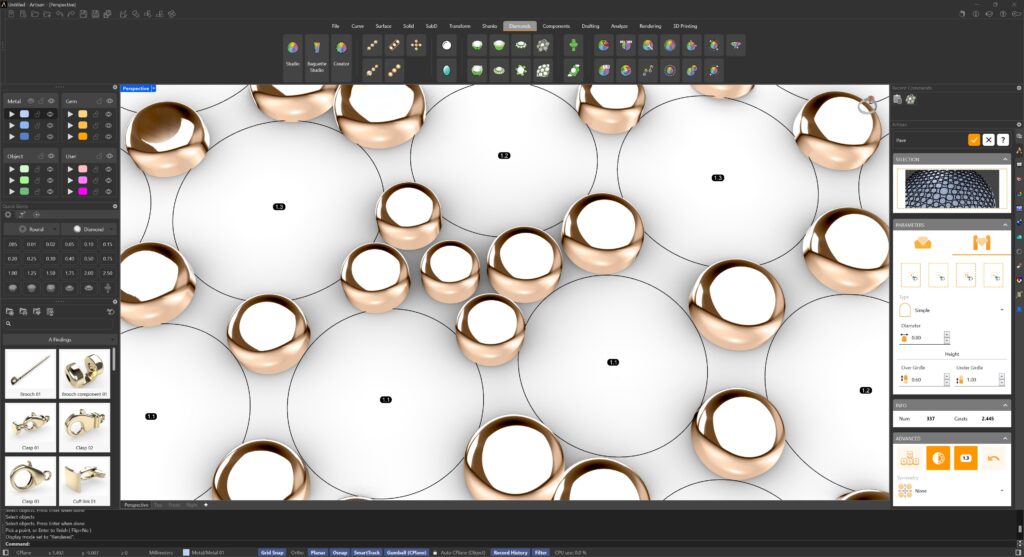

Pavé is a stone setting technique that can transform a piece of jewelry into a dazzling work of art. However, mastering this method requires precision and detailed knowledge of several key factors. At RhinoArtisan, we understand the importance of every detail in designing and making exceptional jewelry. That’s why today we’re sharing our expert tips for achieving flawless pavé. These are the points you should always keep in mind when working with this technique.

Start at the Center

When the piece of jewelry allows it, and especially if it contains stones of very varied sizes, it is advisable to start the pavé from the center. This technique helps to distribute the stones evenly and maintain a visual balance that enhances the beauty of each stone. Starting from the center also makes it easier to make necessary adjustments as you go along, avoiding uneven accumulations of sizes that may clash.

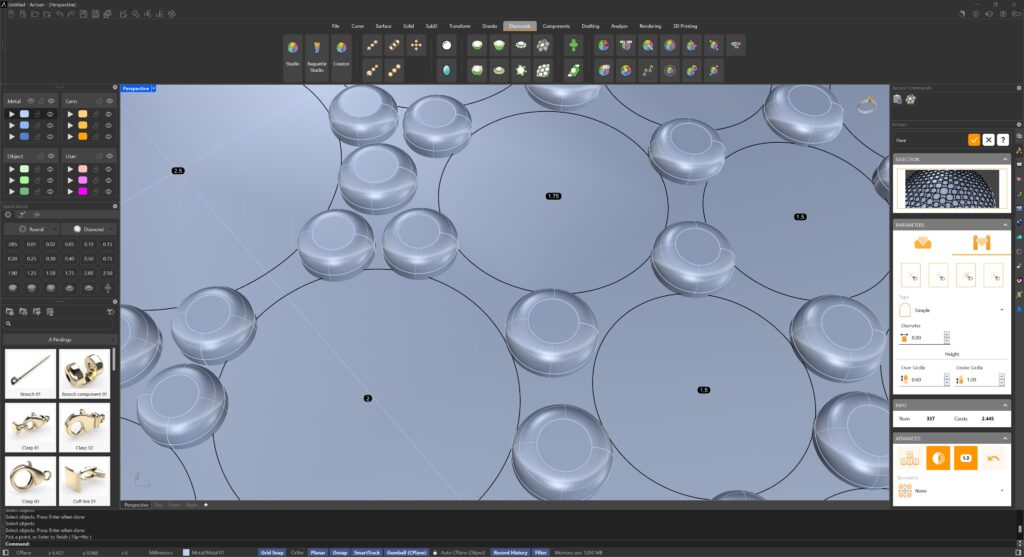

The edge as a starting point for undulating surfaces

If the surface you are working on has many undulations and the pavé will use only one stone size or minimal variations, it is best to start from the edge. This strategy allows you to better control surface variations and ensures that the stones are kept in perfect alignment, respecting the natural curves of the piece.

Leave a margin for corrections

It is crucial to leave a sufficient margin at the edge of the pavé. This extra space will allow you to make corrections to the rest of the design without compromising the integrity of the stones or the pavé pattern. A good margin ensures that the final result is neat and professional.

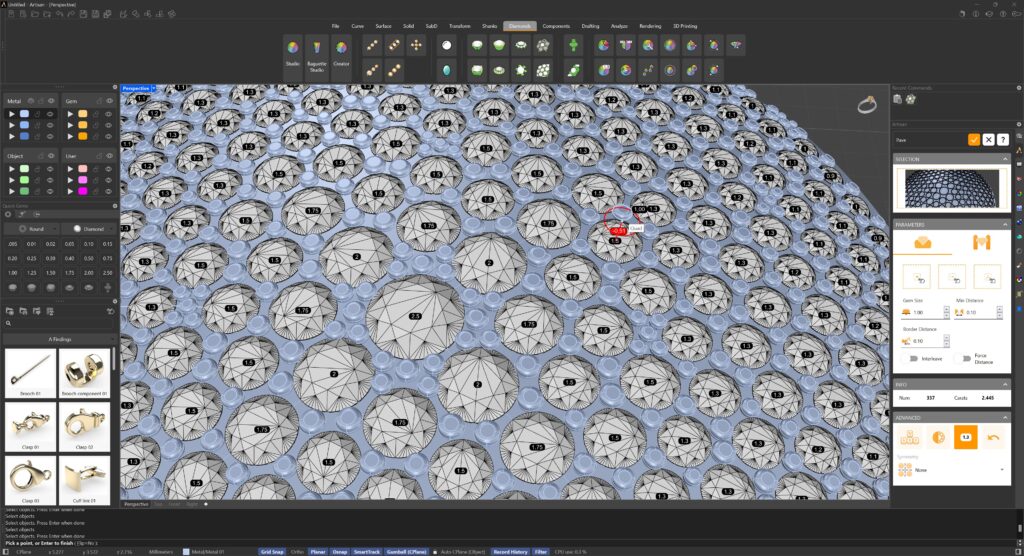

Maintain a minimum distance between stones

Maintaining a minimum distance of 0.25 mm between stones is essential to ensure that the diameter of the prongs does not fall below 0.45 mm. When the thickness of the prongs drops below 0.40 mm, the printing process and the holding of the stones begin to lose consistency. It is not impossible to work with smaller sizes, but it compromises the durability and firmness of the setting.

0.45 mm grains for secure crimping

To ensure a secure setting, we recommend using 0.45 mm grits. This allows the stone to be seated and the prong to be undercut with a concave bur, allowing the point of the prong to push down and hold the stones tangentially. With less thickness, not enough burr will be generated to rest on the crowns of the stones, compromising the hold.

Avoid prongs that are too long

Do not leave the prongs too long; a thickness of 0.50-0.60 mm is sufficient. If they are too long, they increase the likelihood that they will break during cleaning of the impression wax. In such cases, it is better to replace them directly once the part is cast in metal, which can be a complicated task. A thickness of 0.8 mm would already be excessive and not recommended.

Fills empty spaces with false grains

The more stones you place on the pavé surface, the better the final appearance. However, on curved surfaces or when different sizes of stones are used, there may be areas where no other stone will fit, creating visible gaps. In these cases, it is better to fill these spaces with false grains or prongs that do not touch any stone. When finishing and polishing the piece, the brightness itself will hide these gaps, avoiding smooth areas that are difficult to polish and polish and that would stand out negatively.

At RhinoArtisan, we are proud to offer the best 3D jewelry design software that facilitates the creation process and guarantees spectacular results. By following these tips, you will be able to elevate the quality of your pavé designs, ensuring that each piece not only meets the highest industry standards, but also leaves a lasting impression on your customers.