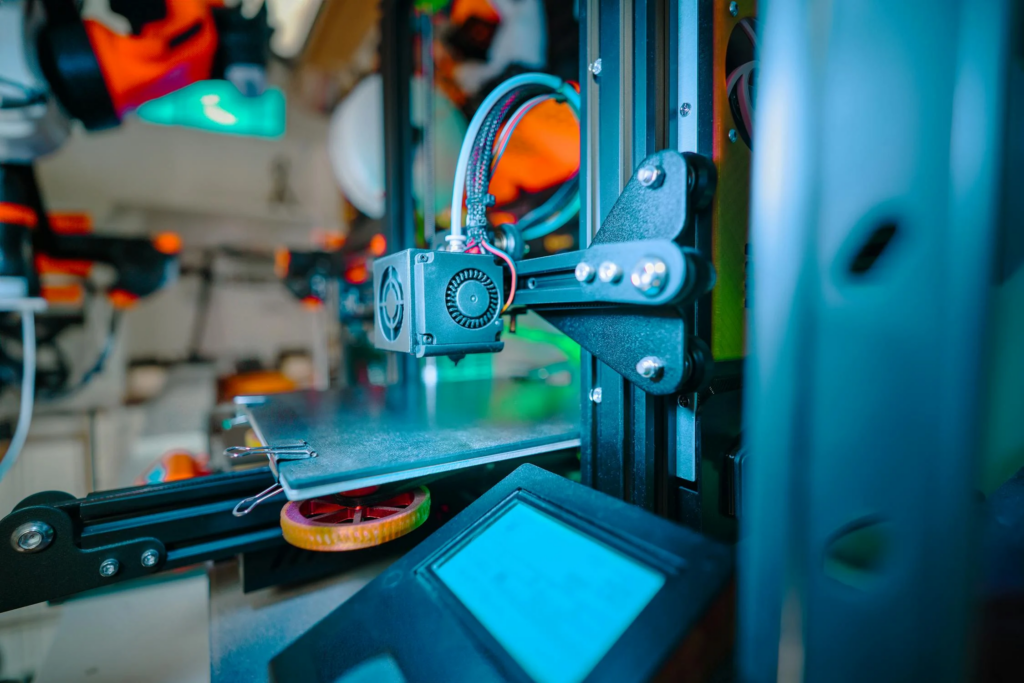

In the intricate world of jewelry making, precision and quality are essential. The advent of 3D printing has transformed the industry, enabling jewelers to create detailed designs with unparalleled accuracy. Among the various 3D printing technologies, SLA (Stereolithography) printers and Material Jetting printers stand out as the best options for production purposes. Let’s explore these technologies and highlight the top five printers suitable for jewelry making.

SLA Printers: Precision and Affordability

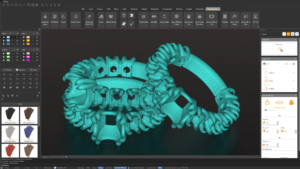

SLA printers have become popular for small-scale production and occasional use, offering an excellent balance of cost and quality. These printers use photopolymer resins, which are cured layer by layer using a laser or UV light, producing finely detailed models ideal for casting.

Advantages and Drawbacks of SLA Printers

SLA printers are known for their high resolution, allowing jewelers to create intricate designs. They are also cost-effective, making them a viable option for smaller workshops. Additionally, SLA printers are relatively fast, providing quicker turnaround times compared to other technologies.

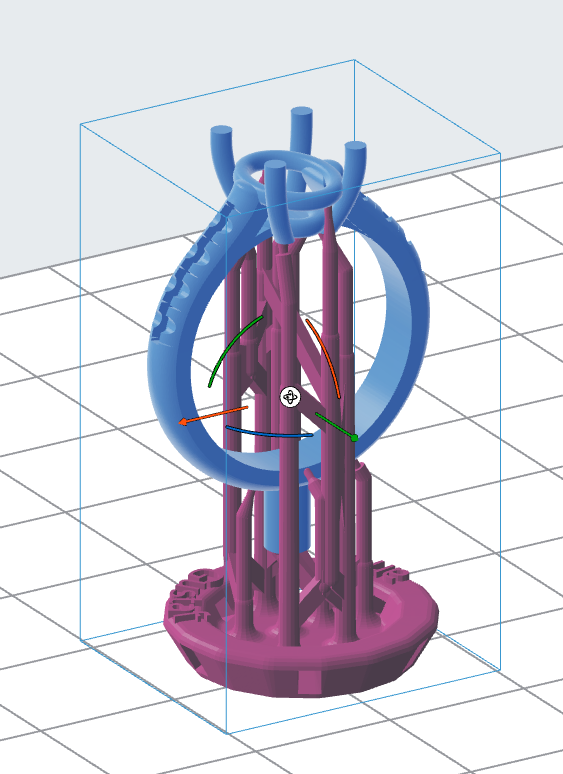

However, models often require support structures to prevent deformation during printing. These supports need to be removed post-printing, which can leave minor imperfections that need to be polished. Earlier SLA resins were prone to burning during the casting process, causing mold damage. Thankfully, advancements in resin formulations and mold coatings have largely mitigated this issue.

Top SLA Printers for Jewelry Making

Three SLA printers stand out for jewelry making:

- Formlabs Form 3: Known for its ease of use and high resolution, the Form 3 is ideal for intricate designs.

- Asiga Max: Offers exceptional accuracy and a wide range of compatible resins, making it versatile for various applications.

- B9 Creations B9 Core 550: Delivers high precision and speed, perfect for detailed pieces.

Material Jetting Printers: Professional-Grade Performance

For those requiring the highest quality and larger scale production, Material Jetting printers are the best choice. These printers use wax materials—one for construction and another for support—ensuring clean and precise results.

Advantages and Drawbacks of Material Jetting Printers

Material Jetting printers offer superior resolution, resulting in clean and detailed final products. The support wax can be easily removed, leaving a flawless surface ready for casting. The wax burns out cleanly without leaving residues, ensuring high-quality casting results.

However, the advanced technology and materials used in Material Jetting printers make them more expensive than SLA printers. Additionally, they are generally slower, which can affect turnaround times.

Top Material Jetting Printers for Jewelry Making

Two Material Jetting printers are particularly noteworthy:

- Solidscape S350: Known for its high precision and smooth surface finish, the S350 is a top choice for professional jewelers.

- 3D Systems ProJet MJP 2500W: Produces high-quality wax models ideal for casting, suitable for larger production runs.

Choosing the right 3D printer for jewelry making depends on your specific needs and production volume. SLA printers, with their high resolution and cost-effectiveness, are excellent for smaller workshops and occasional use. On the other hand, Material Jetting printers, despite their higher cost and slower speed, provide unmatched quality and are ideal for larger-scale operations. By selecting one of these top-tier printers—whether it’s from Formlabs, Asiga, B9 Creations, Solidscape, or 3D Systems—you can ensure that your jewelry designs are produced with the precision and quality your craftsmanship deserves.